Crusher Machine

PAGE 3

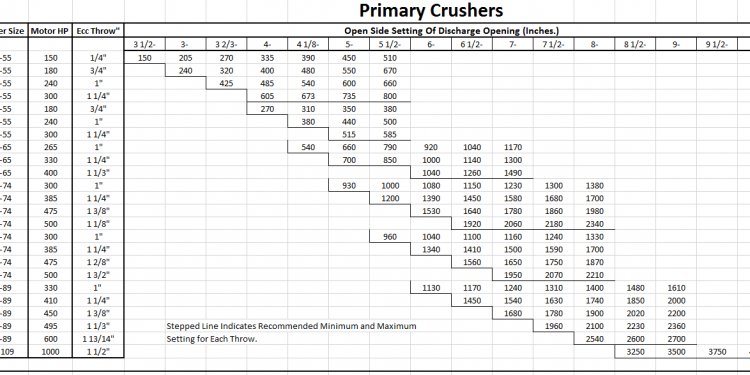

Jaw Crusher Machine

With 1270mm (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable crushing machinery. Maximum productivity is delivered through the enhancements to the jaw box including heavier flywheels and optimization for all crushing applications. The J50’s jaw speed leads to better reduction and material being…

Read more

Crusher dust uses

Q. I ve been enjoying your program on our local NPR station, WSCL in Salisbury, MD. I ran across an intriguing article in the UK s Independent about an apparently miraculous growth medium for plants called rock dust. Sounds like this stuff is right up there with corn gluten meal. I hope you have an opportunity look into this and perhaps comment on it in future broadcasts. Best…

Read more

Ice Crusher Machine Price

Experiencing hot weather is frustrating. This is when you sweat too much and experience discomfort when you move. One of the most agitating moments is that you will feel dry like a desert. For this kind of problem, there is a simple solution that you need—a cold refreshment. If you think that putting ice cubes will suffice, then you might have a problem of waiting for it to…

Read more

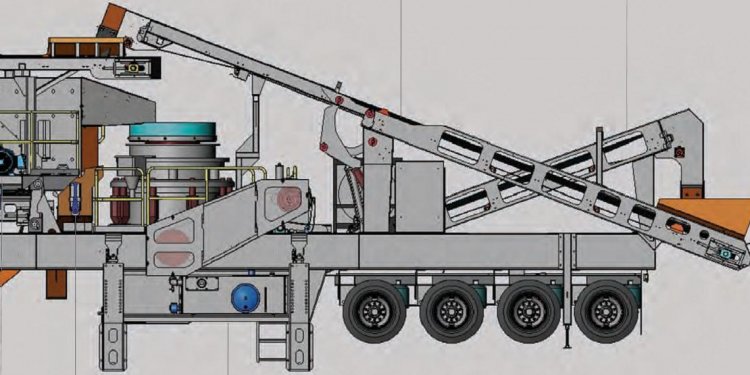

Gyratory Crushers

The Nordberg GP7’s process throughput is the result of constant feed opening combined with its steep cavity. The cavity and easily changeable stroke ensures high performance when using a power rating as high as 560 kW (750 hp). Long lasting liners, efficient adjustable stroke and large setting range bring optimal use of high power. The feed opening of 450 mm (18”) remains constant…

Read more

Impact Crushers

What is an Impact Crusher? Impact size reduction incorporates striking to pulverize material. The primary types of impact crushers include - horizontal shaft impactors (HSI), cage mill pulverizers, and vertical shaft impactors (VSI). Each impactor can be further designated as primary and secondary rotor crusher as well as tertiary and quaternary crushers. This particular designation…

Read more

Can Crusher information?

Can crusher is a simple tool that is used for aluminum can crushing. But this simple tool can be categorized in multiple smaller categories. Aluminum can crushers can be divided by their operation, placement, material and capacity or size of cans they can crush. Let’s start by dividing aluminum can crushers by their operation. By operation By operation can crushers can be divided…

Read more

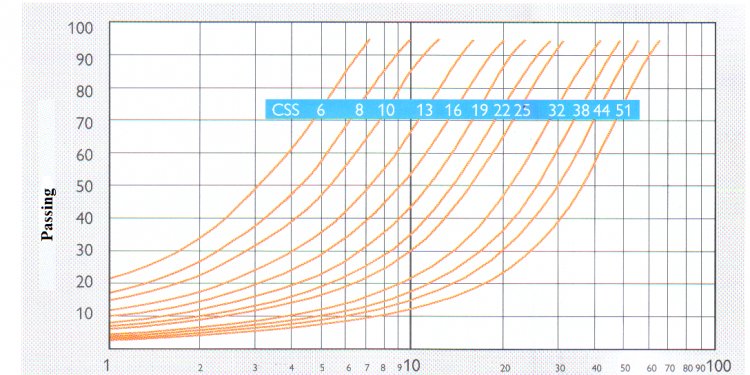

Cone Crushers

We have a long history of developing cone crushers, and we understand how to give you the ultimate setup for maximum productivity and profitability. Today we have thousands of cone crushers in operation around the world including the leading CS and CH cone crusher series. The knowledge we gain is passed on to you in the form of refinements and valuable advice. Sandvik Cone…

Read more

Gold Crusher

During the rush to the gold fields of the 1800s, a LOT of gold was removed from the rivers and banks of the Western US and Alaska. The old-timers used very ineffective methods, but a lot of gold was taken out of the streams and banks. That gold had been setting there for hundreds if not thousands of years. It takes time for the waterways and banks to replenish the gold that…

Read more

Cone Crusher Supplier

This machine is our product of the spring loaded cone crusher partially upgraded with structure improved by adopting the multi-cylinder hydraulic technology, based on the high efficient cone crusher; It is more economic in use. This series of machine is mainly suitable for hydropower project, building, road construction, mine with hardness of crushed stone not exceeding 300Mpa…

Read more

Gyratory Crusher working

The choice between gyratory and jaw crushers in primary installations is governed by a number of factors, including the required throughput and product size, run-of-mine rock characteristics in terms of size, abrasiveness and stickiness, available installation space and access, feeding system and budgetary considerations—both current and with respect of any potential expansion…

Read more

Horizontal Shaft Impact Crushers

The PFC3D (particle flow code) that models the movement and interaction of particles by the DEM techniques was employed to simulate the particle movement and to calculate the velocity and energy distribution of collision in two types of impact crusher: the Canica vertical shaft crusher and the BJD horizontal shaft swing hammer mill. The distribution of collision energies was…

Read more

Crusher Design

The performance of crushing equipment in mineral processing circuits is often critical to the generation of final product. A multi-objective evolutionary algorithm has been developed that allows the crusher internal geometry to be created and evaluated against multiple performance objectives. The multiple-objective approach is particularly important in mineral processing, as…

Read more

Hydraulic cone Crusher

Manual cavity clearing can take up to 5 hours and is very dangerous… Automated cavity clearing is absolutely safe and has you back in operation in less than 15 minutes! Keep your employees safer… and your operation more profitable! Product Highlights: Simplifies Crusher Cavity Clearing with the Turn of a Switch and Push of a Button Drastically Reduces Costly Downtime with Virtually…

Read more

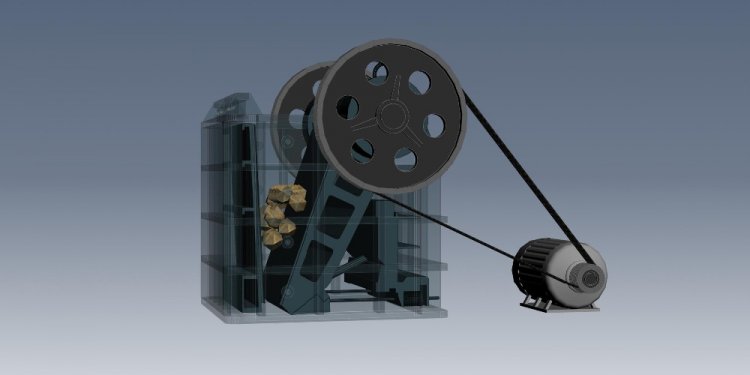

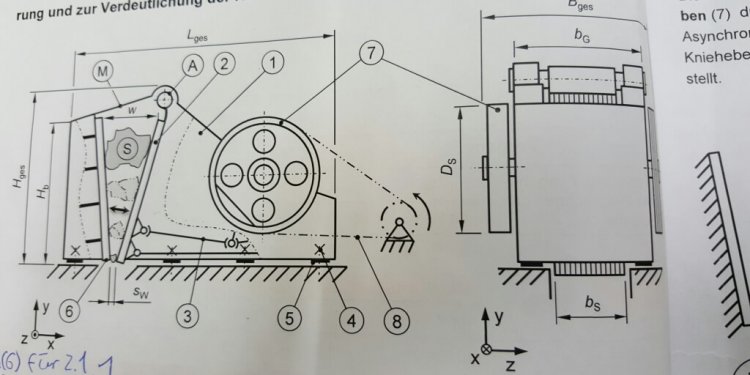

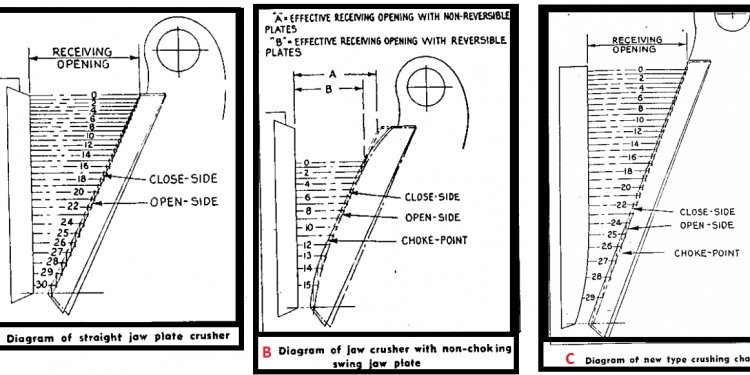

Jaw Crusher Diagram

Has been developed in a variety of forms that probably out-rivals the variations of the gyratory crushing principle. Several different types of motion have been devised, and a great deal of mechanical ingenuity has been displayed in the design of mechanisms to generate these motions. Despite the infinite variety of details, however, most of the jaw crushers in popular usage…

Read more