Asphalt milling machine manufacturers

Summary Statement

This four-page guidance contains a review of dust controls that are now available on half-lane and larger asphalt pavement milling machines as the result of a successful ten-year collaborative effort by industry, management, labor, and government through the Silica/Asphalt Milling Machine Partnership. Members of the Partnership include the National Asphalt Pavement Association, numerous paving contractors, all U.S. and foreign manufacturers of milling machines sold in the U.S., the Association of Equipment Manufacturers, the International Union of Operating Engineers, the Laborers' International Union of North America, OSHA, NIOSH, and FHA. The guidance explains how to reduce silica dust exposure and how to maintain dust control systems through a daily dust control checklist.

March 2015

According to the National Institute for Occupational Safety and Health (NIOSH),

- inhaling respirable crystalline silica can cause silicosis, a debilitating and potentially fatal lung disease.

Silica exposure has also been associated with lung cancer, chronic obstructive pulmonary disease (COPD), and renal disease

Silica exposure has also been associated with lung cancer, chronic obstructive pulmonary disease (COPD), and renal disease - at least 1.7 million American workers in a variety of industries and occupations, including construction, are exposed to respirable crystalline silica and many workers’ exposures exceed current occupational exposure limits

- 0.05 mg/m3 is NIOSH’s respirable crystalline silica Recommended Exposure Limit (REL) to reduce the risk of developing silicosis, lung cancer, and other adverse health effects

- silica dust controls such as ventilation controls used in combination with water-spray controls on asphalt pavement milling machines can consistently reduce exposures below the NIOSH REL and the proposed Occupational Safety and Health Administration (OSHA) Permissible Exposure Limit (PEL)

These guidelines and the dust controls that are now available on half-lane and larger asphalt pavement milling machines are the result of a successful ten-year collaborative effort by industry, management, labor, and government through the Silica/Asphalt Milling Machine Partnership. The Partnership was established in 2003 to find a way to control workers’ exposure to respirable crystalline silica during asphalt pavement milling in highway construction. Members of the Partnership include the National Asphalt Pavement Association, numerous paving contractors, all U.S. and foreign manufacturers of milling machines sold in the U.S., the Association of Equipment Manufacturers, the International Union of Operating Engineers, the Laborers' International Union of North America, the Occupational Safety and Health Administration, the Federal Highway Administration, and the Centers for Disease Control and Prevention National Institute for Occupational Safety and Health.

Members of the Partnership include the National Asphalt Pavement Association, numerous paving contractors, all U.S. and foreign manufacturers of milling machines sold in the U.S., the Association of Equipment Manufacturers, the International Union of Operating Engineers, the Laborers' International Union of North America, the Occupational Safety and Health Administration, the Federal Highway Administration, and the Centers for Disease Control and Prevention National Institute for Occupational Safety and Health.

Recognize the hazard.

Recognize the hazard.

Milling, cutting, or otherwise disturbing asphalt pavement can create airborne dust containing silica. Pay attention to wind direction and any visible dust emissions.

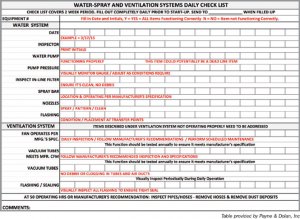

Use ventilation and water-spray controls on asphalt pavement milling machines.

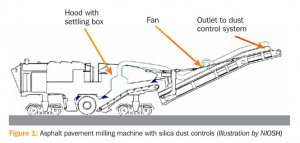

Water-spray plus ventilation controls are collectively considered to be the best practice approach to asphalt pavement milling dust control. Ventilation controls used in combination with water-spray controls can consistently reduce exposures below the NIOSH REL. Typical ventilation controls designed to reduce silica exposures on asphalt pavement milling machines include a collection hood, fan, and ductwork as shown in Figure 1. Milling machines should also be designed to allow the operator to temporarily turn the ventilation control off when milling into the wind. If the ventilation control can be shut off, however, then a feature should be in place to automatically turn the ventilation control back on when it has been off for longer than 60 minutes. Water-spray controls should always remain ON regardless of wind direction.

Always use water-spray controls on asphalt pavement milling machines that do not have ventilation controls.

When ventilation controls are unavailable, water-spray systems that are properly designed, operated, and maintained can provide a significant reduction in the milling machine’s dust generation.