Building Construction tools And Equipment

Every construction project has its own individual needs. Each is different and may have special requirements. That being said, below are suggestions for the type of equipment you will need to erect a metal building.

Every construction project has its own individual needs. Each is different and may have special requirements. That being said, below are suggestions for the type of equipment you will need to erect a metal building.

It’s always good to take inventory, and replace outdated or worn out tools and equipment. Now is the time for Spring Cleaning, so let’s go through the company closets and see what you have and what you need.

Just getting started? This provides a good basic list that will help you with most metal building erection projects.

For unloading and storage

The truck arrives with the building, which is all in pieces and bundles. Getting it off the truck in good shape and arranging it neatly will go much faster and smoother with some basic tools.

Forklift, crane, or other power loader

These bundles are not lightweight. A forklift and some nylon band slings will be needed to offload and transport each bundle to its place.

Blocking

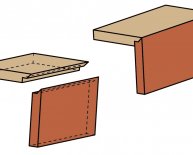

Blocking materials protect the splice plates and the slab from damage while you are unloading. They provide a lift for the materials so you can slip slings or cables around members for lifting. You can also use blocks when bolting together subassemblies while they are on the ground.

Coverings

It’s best to put everything under a roof but it that isn’t possible, place the panels and members on a plastic ground cover and cover them with a waterproof tarp.

For erection and assembly

Variable grip wrenches and a cordless drill with a screwdriver bit are two of the most basic tools. Here is a relatively comprehensive list of tools. You won’t need all of them for every job; check the erection manual from the prefabricator for specific tools. For larger buildings you may need a scissor lift or crane lift.

For safety

Maybe this should be on top because, as always, SAFETY FIRST.

OSHA

Follow OSHA guidelines.

Let me say that again.

Follow OSHA guidelines.

OSHA can levy fines if you are found out of compliance and that gets expensive in a hurry.

Personal protective equipment (PPE)

Every worker should have the appropriate personal protective equipment for the job he is doing at the time. Whether the worker is at height or is using certain equipment, make sure you and your crew understand how important the right PPE is.

Additional safety equipment includes, of course, one or more fire extinguishers. These should be checked regularly for a charge. Near the extinguisher is a good place to keep a first aid kit. The kit should contain, at a minimum:

Train everyone on the use of the personal protective equipment. A basic first aid course wouldn’t hurt. You may need more supplies that this depending on the types of injuries that occur most often on your jobsites. Anytime the first aid kit is used, make sure it is restocked as soon as possible. If everyone is careful, you won’t have to do that too often.

If at all possible, develop and perform a hazard assessment for each jobsite. Identify potential dangers as early as possible and work to mitigate or eliminate them. Put someone in charge of safety who can make sure everyone maintains and uses their protective equipment properly and who maintains the hazard communication policy and practice.

Erecting a metal building, no matter the size, requires attention to safety and the right tools. This post is, by no means, a comprehensive list of what you will need for every job but it does mention many of the tools that will be put to use each day. Consult your erection manual for specifics for your metal building.