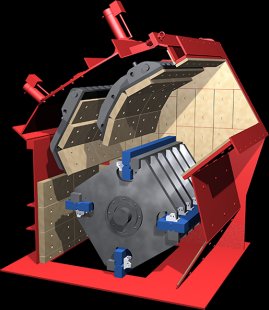

HAZEMAG Impact Crusher

The HAZEMAG APS - Series Secondary Impact Crusher is ideally suited to crush medium-hard materials down to a highly cubical, well graded product size of 0 - 3 inch (65% -1 inch) in a single pass. This machine is normally offered within a plant/system where tertiary crushing is also present. However, due to its high reduction ratio the need for multiple secondary units is normally eliminated.

The HAZEMAG APS - Series Secondary Impact Crusher is ideally suited to crush medium-hard materials down to a highly cubical, well graded product size of 0 - 3 inch (65% -1 inch) in a single pass. This machine is normally offered within a plant/system where tertiary crushing is also present. However, due to its high reduction ratio the need for multiple secondary units is normally eliminated.

The HAZEMAG APSH (HAZtronic) - Series Secondary Impact Crusher offers a level of impactor performance and apron positioning/ control technology that ensures the production of a high quality, consistent product gradation. The APSH HAZtronic (HAZtronic = Hydraulic Apron Adjustment / Programmable Apron Settings) system is available on most APS & APSM secondary impactor models. The computer controlled, fully automated hydraulic apron positioning system puts you in control, helping you produce the products you sell the most! Additional details on this system are covered within this brochure - HAZtronic System.

The HAZEMAG APSM - The HAZEMAG APSM - Series Secondary Impact Crusher (M = Third Crushing Path) is ideally suited to reduce medium-hard materials down to a highly cubical, well graded product size of 0 - 2 inch (85% -1 inch) in a single pass. Due to its very high reduction ratio and added control over the upper product size, this impactor can efficiently operate in closed circuit on smaller product size fractions. This machine is ideally suited for plants that require high levels of product size and shape control. The HAZEMAG APK - Series Secondary Impact Crusher is ideally suited to crush medium-hard materials down to a highly cubical, well graded product size of 0 - 3 inch (60% passing 1 inch) in a single pass. This machine is normally offered within an aggregate plant / system where tertiary crushing is also present. However, due to its high reduction ratio, the need for multiple secondary units is normally eliminated.The HAZEMAG APKH (HAZtronic) - Series Secondary Impact Crusher offers a level of impactor performance and apron positioning / control technology that ensures the production of a high quality, consistent product gradation. The APKH HAZtronic (HAZtronic = Hydraulic Apron Adjustment / Programmable Apron Settings) system is available on all APK and APKM secondary impactor models. The computer controlled, fully automated hydraulic apron positioning system puts you in control, helping you produce the products you sell the most! Additional details on this system are covered within this brochure – HAZtronic System.

The HAZEMAG APKM - Series Secondary Impact Crusher (M = Third Crushing Path) is ideally suited to crush medium-hard materials down to a highly cubical, well graded product size of 0 - 2 inch (75% passing 1inch) in a single pass. Due to its very high reduction ratio and added control over the upper product size, this impactor can efficiently operate in closed circuit on smaller product size fractions. This machine is ideally suited for plants that require high levels of product size and shape control.