Drill Cement Mixer

Having just one 5 gallon bucket of concrete ensures fresher mud without extra transfer work. If you have to take a phone call, cleanup is fast. Waste is minimal. Much larger mixers make sense with larger crews. Today's affordable and lightweight drills make hand held mixing possible (and can even run off solar panels) . First a warning is given: Hand held power tools can overwhelm either a user, the power too litself or things nearby. A beginner should approach such work with great care and personally assume all risk.The pages of this website are offered only as a free exchange of personal experience and evolving ideas. The versitility and portability of the electric drill has proven useful in cement mixing. This research looks into ways of mixing with drills, inside of 5 gallon buckets. Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

Having just one 5 gallon bucket of concrete ensures fresher mud without extra transfer work. If you have to take a phone call, cleanup is fast. Waste is minimal. Much larger mixers make sense with larger crews. Today's affordable and lightweight drills make hand held mixing possible (and can even run off solar panels) . First a warning is given: Hand held power tools can overwhelm either a user, the power too litself or things nearby. A beginner should approach such work with great care and personally assume all risk.The pages of this website are offered only as a free exchange of personal experience and evolving ideas. The versitility and portability of the electric drill has proven useful in cement mixing. This research looks into ways of mixing with drills, inside of 5 gallon buckets. Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

A helix impeller which is less than half the bucket width creates a mini whirlpool inside the helix impeller itself. This uses less power than a full bucket sized whirlpool. A small helix acheives layer inversion more efficiently than a small fan like blade, as the whirlpool propels itself inside of bucket. However a full width fan like blade can work very smoothly , given more power. A whirlpool is needed to invert stratified layers within the bucket and mix them. I've been measuring amperage and a full bucket width impeller can run more than 8 amps at 300 to 500 RPM drill speeds. High amperage power surges apply the excess amperage as heat within the motor. We might check this further with precision. Does surging a 7 to 8 amp drill motor from 11 to 16 amps, on a regular basis hurt the motor? May we assume amperage of a drill rating is worth heeding? Very intermittent surging and with lower surges, has, for some users, seemed not to hurt a drill in practice. Perhaps the heat was low enough compared to other cases of motor burnout. A Fluke 36 Clamp On Meter has been used to digitally measure actual electrical current usage, (leading to general opinions on this page).

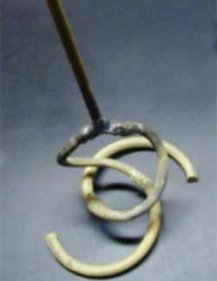

A helix impeller which is less than half the bucket width creates a mini whirlpool inside the helix impeller itself. This uses less power than a full bucket sized whirlpool. A small helix acheives layer inversion more efficiently than a small fan like blade, as the whirlpool propels itself inside of bucket. However a full width fan like blade can work very smoothly , given more power. A whirlpool is needed to invert stratified layers within the bucket and mix them. I've been measuring amperage and a full bucket width impeller can run more than 8 amps at 300 to 500 RPM drill speeds. High amperage power surges apply the excess amperage as heat within the motor. We might check this further with precision. Does surging a 7 to 8 amp drill motor from 11 to 16 amps, on a regular basis hurt the motor? May we assume amperage of a drill rating is worth heeding? Very intermittent surging and with lower surges, has, for some users, seemed not to hurt a drill in practice. Perhaps the heat was low enough compared to other cases of motor burnout. A Fluke 36 Clamp On Meter has been used to digitally measure actual electrical current usage, (leading to general opinions on this page). For example, the "S" shaped impeller pictured below was used to whirlpool a common 5 gallon bucket of mix. A "Superhawg", 13 amp, 450 RPM angle drill was used. Readings generally ranged just under 13 amps for a reasonably thick mortar consistency of mix. Only once or twice, (within several buckets of mixes), did the amperage exceed 13 amps, (just for an instant each time, due to stiffer ingredients). Faster- smaller drills especially need reduced loading and a smaller helix lightens the load and improves the range into difficult, sticky or fibered mud. Bakers were perhaps the first to use slim spiral bits to mix stiff dough. Or was it some other trade? The author started experimenting with junk auto-truck springs for concrete mixing, on a quest for small scale, low tech automation in mixing. That is the quest and motivation for this prototype experimentation. More recently, ultra low cost rebar corkscrew mixers are also tested.

For example, the "S" shaped impeller pictured below was used to whirlpool a common 5 gallon bucket of mix. A "Superhawg", 13 amp, 450 RPM angle drill was used. Readings generally ranged just under 13 amps for a reasonably thick mortar consistency of mix. Only once or twice, (within several buckets of mixes), did the amperage exceed 13 amps, (just for an instant each time, due to stiffer ingredients). Faster- smaller drills especially need reduced loading and a smaller helix lightens the load and improves the range into difficult, sticky or fibered mud. Bakers were perhaps the first to use slim spiral bits to mix stiff dough. Or was it some other trade? The author started experimenting with junk auto-truck springs for concrete mixing, on a quest for small scale, low tech automation in mixing. That is the quest and motivation for this prototype experimentation. More recently, ultra low cost rebar corkscrew mixers are also tested.

Picture Above: A cheaply made mixer experiment using a drill with a car spring for bit/ impeller. It is resting on a simple hanger which can very easily engage an electric trigger switch to allow stirring while adding material. See a building under construction which used only this mixer for tons of concrete mixing. Below, same drill mixer hangs from a welded rebar stand with slow feed hopper. Drill vibration vibrate-feeds dry mix into bucket. Bucket is held by auto wheel with rags tied around to softly grasp the bucket but allows bucket to turn slowly. Some small auto wheels are nicely sized and tapered. (Just cut out hub area). Add just enough rag to hold pail or adjust for slow bucket rotation which wipes the full bucket- Almost hand free operation, while the mix is very wet, (water first). Strategy is to add last of the dry aggregate last. Critical point here: the helix whirl pool might haveto move around bucket or the bucket has to slowly rotate to get the whirlpool to finish mixing all contents of bucket. Some testers have not appreciated this aspect. Beware, it does take determination to prototype tools, to balance spinning impellers and to understand contexts of details.