Jaw Crusher Mechanism

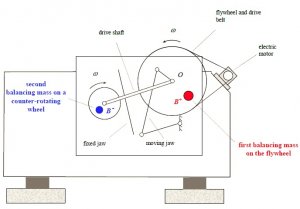

A jaw crusher may be balanced by two balancing masses rotating in opposite directions. By a careful design of the balancing masses approximately 90 % of the inertial forces and vibration amplitudes due to the imbalanced jaw mechanism may be removed. Dual mass balancing serves several benefits such as lower stress, vibration and noise levels of the machine, and an increased fatigue life.

Jaw crushers use compressive force for breaking of particles of all rock and recycle materials. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. The reciprocating jaw moves back and forth and, due to its large mass, creates very big inertia forces which penetrate through the whole structure to the ground or mobile track- mounting.

The new balancing method utilizes two balancing masses rotating with the same speed but in opposite directions. Balancing mass B+ rotates in the same direction than the flywheel and balancing mass B- in the opposite direction than the flywheel. The sizes and locations of the balancing masses of the new balancing method can be optimally designed so that they provide a complete first order balancing.

After a complete first order balancing, the magnitudes of the inertia loads are significantly reduced and their lowest frequency component is twice the rotational frequency of the machine.

After a complete first order balancing, the magnitudes of the inertia loads are significantly reduced and their lowest frequency component is twice the rotational frequency of the machine.

MOTIVATION

The conventional balancing method utilizes one balancing mass mounted on the flywheel. The conventional one mass balancing method only partially cancels the mass imbalance of the jaw crusher mechanism. The remaining force ranges are typically of the order of 100 000 N in a middle-sized crusher. These forces introduce several drawbacks:

- Large cyclic stresses in the machine

- Large forces transferred to the mounting

- High vibration levels and noise

- Fatigue, machine failures and heating of the mounting pads

The inertia forces and the related stresses penetrate through the whole structure to the mounting of the machine.

APPLICATIONS/

IMPACT

The removal of a major part of the inertia forces of the jaw crusher mechanism decreases the stresses and support reaction forces, increases the fatigue life, decreases the vibration and noise levels and reduces the heating of the mounting pads.

- Typically 85-90 % of the stresses and support reaction forces due to mass imbalance are removed when using the complete first order two mass balancing instead of one mass balancing

- The machine can be lightened

- The vibration and noise levels of the jaw crusher are significantly reduced

- Fatigue lifetime in normal run is markedly increased

- Heating of the mounting pads is notably reduced

- The stroke of the moving jaw can be increased yielding an aggressive crushing action